Author: Dave Marshall-George, Sales Director, Condair

Dehumidifier specification - how to size and select a dehumidifier

Key to delivering a successful dehumidifier project is knowing what questions to ask at the outset. There are many variables in lowering humidity. Poor planning can not only lead to the required humidity levels not being achieved, but also the temperature control of an area being significantly compromised or the system not being used due to excessive energy use.

From our experience in delivering thousands of successful dehumidification systems, here is a summary of key things to consider when setting out on a drying project.

What is the temperature of the area?

The temperature of an area is a deciding factor in technology selection. Condensing dehumidifiers work very efficiently in ambient room temperatures of around 20°C. They rely on moisture condensing on a cold surface, so the cooler the air, the less condensation will form.

When temperatures drop to around 15°C or less, condensing dehumidifiers aren’t very effective, so desiccant dehumidifiers become the preferred option. They need more energy to operate and can be a more complicated install, but as they remove water from the air by adsorbing it, they operate well in warm or cool areas.

Both types of dehumidifier will add heat to the air during the drying process so this must also be considered. As water changes state from a gas to a liquid, the thermodynamic process results in around 0.63kW of heat for every 1kg of moisture removed. Desiccant dehumidifiers present even greater heat gain. Hot air is passed through a section of the desiccant rotor to exhaust the adsorbed moisture externally and maintain the rotor’s drying properties. Residual heat from this regeneration process will add even more heat to the process air as it passes through the drying part of the rotor.

If this heat gain causes an area to overheat, people in the room will frequently open windows and ventilate, but this detrimentally impacts the humidity control. Combatting this heat gain with external condenser units on condensing dehumidifiers (similar to split ac units) or with post-cooling modules on desiccants, is an important part of the planning process. The manufacturer should always be able to give information on the level of heat gain a system will deliver and how best to counter it.

What is the required humidity level?

Environments such as clothes drying rooms or swimming pools don’t need extremely arid conditions. Simply maintaining a mid-range humidity of around 50-60%RH is adequate to meet the needs of these projects. However, low humidity environments needed for processes such as battery production or very close humidity control needed in some pharmaceutical manufacturing will mean desiccant dehumidifiers are the only option.

Desiccant dehumidifiers can be placed in series, one after another, with cooling or heating modules to meet an exact environmental condition. This means they can deliver humidity control potentially as low as 1%RH, something unachievable with condensing technology.

... a heat recovery system can be implemented on the out-going regeneration air, to scavenge some of the heat from the exhaust air.

What energy is available?

With the high cost of energy, this question is of paramount importance, particularly for any high capacity project. A condensing dehumidifier is typically the more energy efficient option, as it consumes around 0.5-1.5kW of energy for every 1kg of moisture removed. A desiccant dehum will use 1-3kW of electricity per 1kg removed.

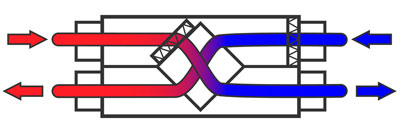

The energy needed to operate a desiccant unit is mainly to heat the regeneration airflow. The temperature of this airstream is 90 to 120°C. If there is waste heat available from another process, this can be used via a heat exchanger to pre-heat the regeneration airstream and reduce the energy burden. To further reduce the energy use, a heat recovery system can be implemented on the out-going regeneration air, to scavenge some of the heat from the exhaust air prior to release. Using both these strategies can significantly reduce the energy burden of desiccant systems.

Where is moisture coming from and how much?

In order to correctly size a dehumidifier, it is vital to understand the quantity of moisture in the air that needs to be removed. To do this all sources of water addition from both internal and external factors must be considered.

The external source of moisture is calculated by factoring in the outside air conditions, the rate of air exchange with the area in question, the size of the area and its required conditions. A psychrometric calculation can then be done to precisely know what amount of moisture a dehumidifier will need to remove from the incoming external air to meet the required indoor condition.

However, any internal sources of water must also be factored in. If the area is a swimming pool, then the internal load will be significant. The pool volume, water temperature and hours of operation will all help calculate the amount of evaporation. People also give off moisture and can do so at varying levels depending on their level of activity.

A dehumidifier manufacturer will be able to help with these calculations but will need specific details to be able to accurately determine the total duty and ultimately what size a dehumidifier will need to be.

The size of the room not only determines the size of dehumidifier but it can also affect ducting

What is the room like and where is it?

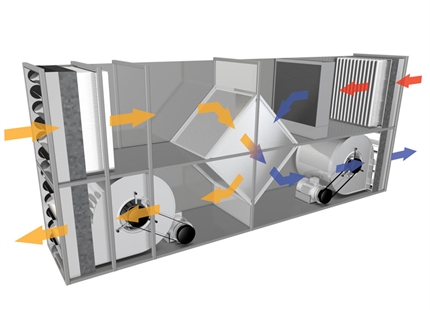

Answers to this question will help determine some install options. Desiccant dehumidifiers will need ducting for the exhaust regeneration airstream. A room centrally located in a building can make this challenging. A condensing system will only need a power and drain connection, which can make for an easier install.

The size of the room not only determines the size of dehumidifier but it can also affect ducting. If the air circulation through a dehumidifier located directly in a room is less than three times the room volume, ducting on the dry air outlet should be considered to uniformly disperse the conditioned air.

Answers to the questions above will help build a solid foundation for a successful drying project. Working with a dehumidifier manufacturer that offers a comprehensive range of both condensing and desiccant systems is also beneficial, as it avoids any selection bias. And lastly, getting advice from the manufacturer early in the project will greatly improve the odds of delivering a successful outcome.