Preventing ice & mist with dehumidifiers

Dave Marshall-George, Sales Director at Condair, explains how dehumidifiers can be used in cold stores and freezers to prevent ice and misting.

Commercial cold stores and freezers are tightly sealed environments, but excess water will always find a way to get in. Cleaning routines, evaporation from produce and people, or simply carried in by the air through open doorways, moisture ingress is inevitable. It can lead to ice on floors, walls and ceilings, frost damage to produce and mechanisms, or air misting and reduced visibility. All of these things will impact an operation’s productivity, profitability, and health and safety. But it doesn’t need to be this way…

Dehumidifiers specially designed for use in this environment will extract humid air from the freezer, remove the excess moisture and return dry air back to the storage environment. This dry air delivery is normally directed to where a problem is being experienced, for instance above an entrance if the issue is doorway icing. Alternatively, it can be in an ante-room or airlock area just outside the entrance, to minimise the volume of moisture initially entering the freezer.

Beyond improving the internal environment of a cold store, removing moisture with a dehumidifier will also reduce the amount of ice build-up on the refrigeration system’s evaporators. By lowering the ambient humidity level, the need to defrost can be significantly reduced and the operating efficiency of the system improved. In some blast freezer projects, we’ve seen the need to defrost be extended from once per week, to once every three months. Additionally, as the dehumidifiers were blowing directly on to the evaporators, leaving them running during the defrost cycle reduced the defrost time from a whole day to just a few hours.

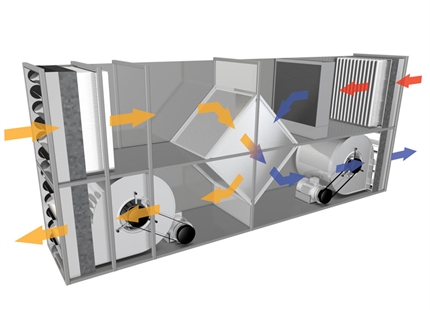

Removing moisture from a cold environment requires desiccant dehumidifier technology, such as the Condair DA. This is a type of dehumidifier that passes wet air through a slowly rotating desiccant rotor. It literally absorbs water from the air like a sponge. As this rotor revolves, a section of it continually passes through a hot air flow, which removes the water and allows the rotor to remain absorbent. This is called “regeneration”.

This type of dehumidifier therefore needs two ducted airflows to operate. A process airflow, which takes air either from the cold store or ante-room area, passes it through the dehumidifier’s drying rotor, then re-introduces the now dry air back to the cold store environment. The other airflow is the regeneration airflow. This draws in fresh ambient air, heats it, then passes the hot air through the rotor to regenerate it, before finally being exhausted externally, along with the moisture it collected from the rotor.

Removing moisture from a cold environment requires desiccant dehumidifier technology, such as the Condair DA.

This type of dehumidifier isn’t unique to cold store projects, as it’s used in many close control, low humidity or low temperature drying applications. But there are some features that are specifically needed for successfully drying a cold store or freezer. These can include exceptionally thick insulation, a thicker than normal rotor, different rotor speeds, special heaters, and pressure configurations that avoid the potential for air leakage and undesirable thermal transfer that will lead to internal freezing or condensation.

Over many cold store and freezer projects, Condair’s freezer dehumidification systems have been tailored to include a very flexible range of options to suit any cold store requirement. Models are available that can be located outside the cold store, in an ante-room or airlock area, inside the cold store or even outside the building. Each strategy has pros and cons, but a particularly useful feature is the energy savings that are possible only when placing the dehumidifier outside the cold store.

As these systems are operating 24/7, minimising energy consumption is vital. The majority of the energy used by a desiccant dehumidifier is for heating the regeneration airflow. In cold store applications, it’s possible to use the fridge system’s condenser coil to heat this airflow. Using this energy source alone can be sufficient to get the air to 65-70°C and obtain enough drying capacity to achieve a project’s humidity control objectives. This strategy is not possible when installing the dehumidifier inside the cold store.

Another energy saving feature involves using a heat recovery system on the exhaust side of the regeneration airflow. Before the hot wet air is vented, running it through a heat recovery unit can transfer around 75% of the energy back to pre-heat the incoming regen airflow. Incorporating both these strategies can see a dehum’s energy consumption reduced significantly and could result in a net reduction in overall energy use, when considering the improved efficiency and energy savings on the chiller plant.

Alongside the energy saving benefits that are possible by locating the dehumidifier outside of the cold storage area, there are other advantages. Servicing is much simpler, as engineers can operate in ambient conditions. The dehumidifier can be turned off without any risk of internal moisture freezing, causing issues with moving parts. Also, due to the low temperatures, PLC controllers aren’t an option for units inside the freezer, limiting the functionality of the system. And lastly, dehumidifiers are large and if located inside a cold store, will take up a lot of valuable storage space.

But whatever location or energy saving options are selected for a project, being able to proactively reduce the humidity of the air inside a freezer environment has obvious benefits for commercial operators and can produce rapid return on investment.